Shear Frame

DownloadShearFrame_manual (PDF, 1002 KB)vertical_align_bottom

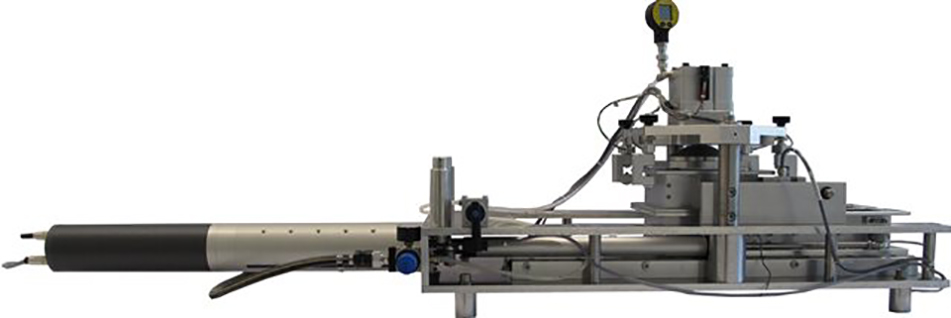

The process of shearing is the counter movement of two frames located on each other.

The Shear Box is designed to measure acoustic emission. Therefore the maximal displacement is longer and the shear velocity can be adjusted in a broad range. The shear box can work either in a strain controlled mode with constant speed or in a load controlled mode with constant load. Additionally a piston is mount to the top frame to consolidate the observed soils or granular matter.

The lower frame is longer and mobile in one horizontal direction while the upper frame has no degree of freedom. The upper frame’s bearings are force transducers to allow measuring all process forces in horizontal and vertical directions and correcting the calculated values for wall friction. The consolidation as well as the shear movement is measured and logged with displacement sensors.

All measurements are analog are recorded with a data logger and displayed on a screen with a GUI programmed in LabView. At the bottom of the lower frame is a porous plate which allows setting suction up to 400mbar to the sample material. Suction matrix potential can be measured at two different depths below the shear plane via tensiometer. There are designated bore holes for connecting acoustic sensors inside of the soil.

Team: Dani Or, Gernot Michlmayr, Dani Breitenstein

Contact: