Modeling stress fluctuations and stick-slips of granular materials using the fiber bundle model

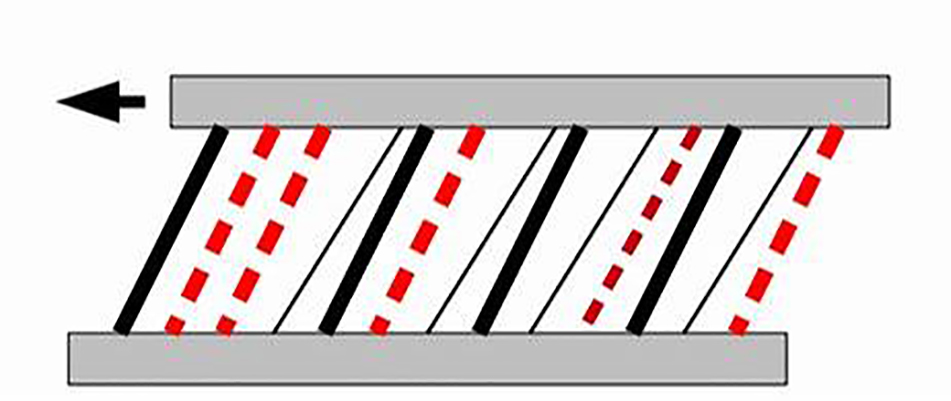

Granular materials can exhibit stress drops during strain-controlled shear deformation and stick-slip dynamics when sheared under a constant force. These behaviors arise because of local rearrangements of grains causing non-uniform stress distributions and the formation of force chains that can jam the system. A fiber bundle model (see Figure below) can be used to reproduce these stress-drops and also stick-slip characteristics. Statistics of stress drops and acoustic emissions, as well as measures of the energy released during such events, will be used to compare model to experimental results. The aim of this model is to help to identify different granular regimes that exist under different shear rates, normal loads, grain sizes, and thickness of the deforming shear zone.

Figure 1: Sketch of the stick-slip fiber bundle model. Two rigid plates are moved parallel to each others which causes straining of the fibers in between. According to their individual rupture threshold fibers may withstand different levels of loading, which leads to disordered failure of the fiber bundle.

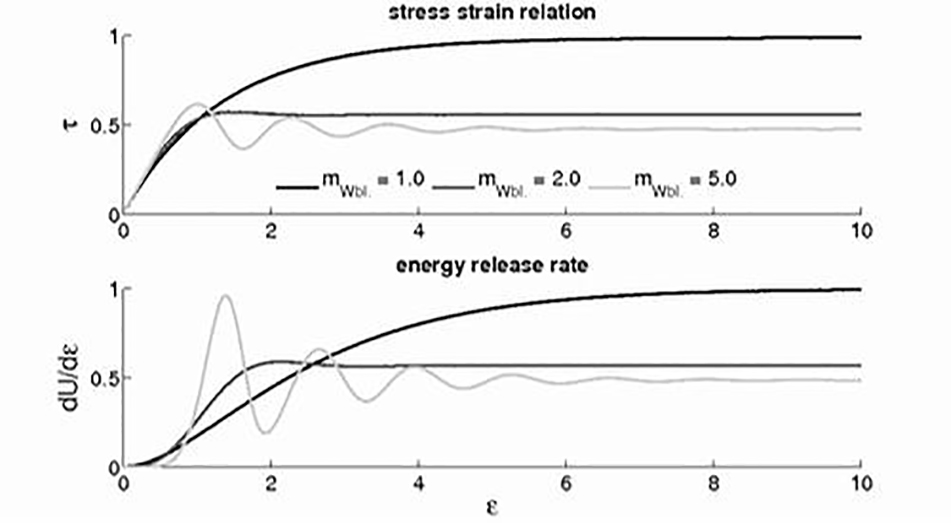

Figure 2: Simple representations of the fiber bundle model (in this example Weibull distributed fiber strengths, with shape parameter m and no restriction on the maximum number of failures a fiber can suffer) may deliver analytical solutions for the stress strain behavior or for the energy that is released through fiber rupture. Latter plays an important role for establishing a link to acoustic emission measurements obtained from shear tests with granular material.

Team: Dani Or, Gernot Michlmayr

Funding: CCES

Students: Gernot Michlmayr

Contact: